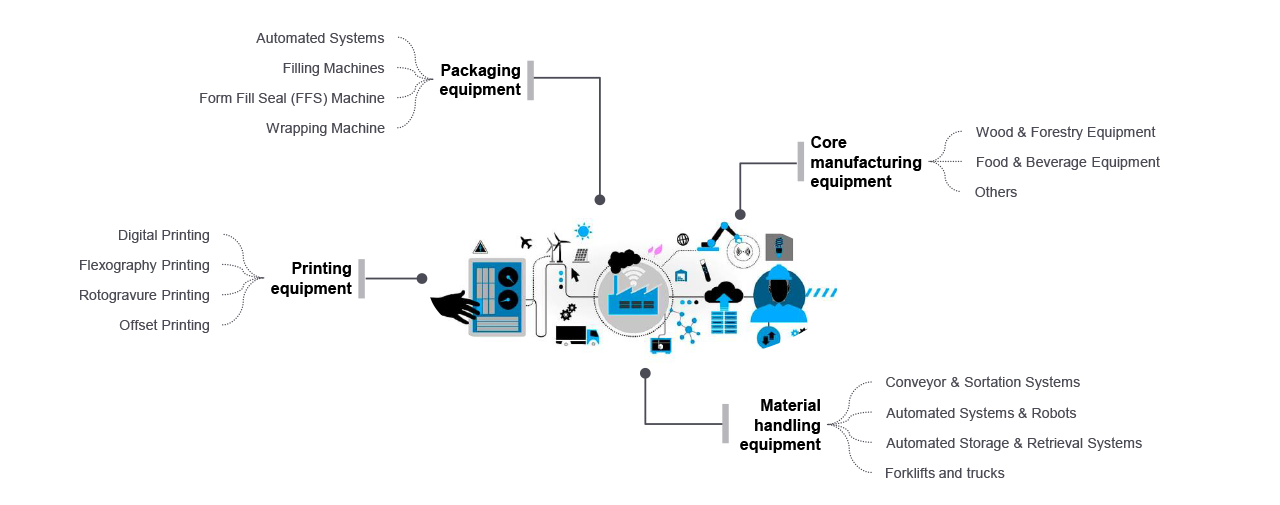

Manufacturing Equipment

Optimization. Digitalization. Automation.Equipment providers in the manufacturing sector are focusing on improving the productivity and efficiency of machines. With increasing concerns on operational cost optimization, including improving the OEE, equipment providers will face stiff competition to offer automation and digital products, emphasizing digital OEE, continuous improvement, lean manufacturing, and manufacturing execution systems.

Industrial Manufacturing

Emerging Non-thermal Technologies in Food Processing

Industrial Equipment

Factory of the Future – Roadmap and Actions

Strategic Growth Fields

A convergence of industry transformations and exponential technologies creates a pool of opportunities

Robotics & Automation

- RaaS

- Co-Bots

- Automation architecture

As-a-Services Models

- Equipment-as-a-service

- Product as-a-service

- Results as-a-service

Industry X.0 & Digitalization

- Virtualization

- Advanced sensors and communication

- Digital OEE

Lean

- Operations improvement

- Strategic sourcing

- Value stream mapping

Business Objectives

Some examples of diverse business objectives we have worked with our clients

Strategy & Futures

- Which end-user segments should the client investigate for specific manufacturing equipment?

- How are the customer needs changing for core manufacturing equipment?

Research Development & Innovations

- Which technologies are cost-effective, where the client can invest?

- Which technologies do customers prefer currently, and why?

Growth & Market Development

- What are the current demand and future market potential for specific equipment?

- Who are the key market players? What are their market shares, product offerings, and USPs?

- At what prices do end-users buy this equipment?

Manufacturing, Production & Logistics

- Which are the best low-cost sourcing destination for procurement of parts and components used in our equipment?

- How is the industry reacting to predictive and preventive maintenance? What initiatives can be taken to remain competitive?

Client's Success Stories

Industrial ManufacturingDigitalization (equipment as a service, digital twins)

Strategy Development based on Digitalization Offerings and As-a-Service model

Industrial Manufacturing