|

Cobots, or collaborative robots, are a new breed of industrial robots that are designed to work safely and efficiently alongside human workers. Unlike traditional industrial robots, which are typically large, powerful, and expensive, cobots are smaller, lighter, and more affordable. They are also much easier to program and use, making them ideal for a wide range of manufacturing and assembly tasks. Cobots are already having a major impact on the industrial robotics market, and their popularity is only expected to grow in the years to come. Cobots were first envisioned in the early 1990s to make robots safer for humans to work with. Early cobots were simple, but advances in sensors, AI, and robotics have made them much more sophisticated and capable. In this article, we will explore the concept of collaborative robots, their key features, applications, and the impact they are likely to have on the future of industrial robotics. |

|

What makes a Robot Cobot?

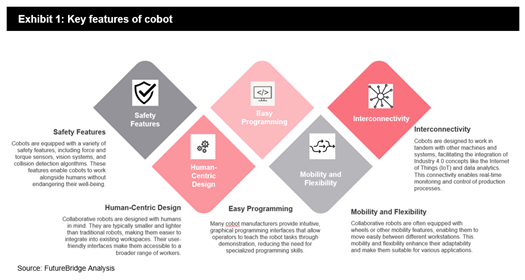

The traditional industrial robots excel in heavy-duty, high-precision, and mass-production environments, cobots are designed to be safe, flexible, user-friendly, and cost-effective for collaborative tasks in shared workspaces. Cobots incorporate safety features like sensors, cameras, and advanced software to operate safely alongside humans without the need for protective barriers. Cobot designs tend to avoid sharp edges and pinch points and limit force and speed to reduce the chance of injury.

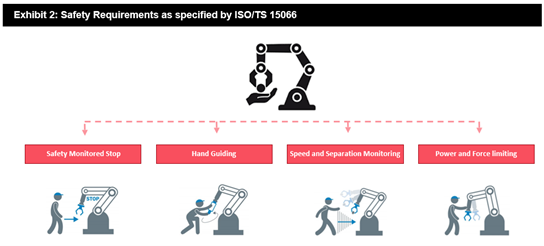

According to ISO 10218, from the International Organization for Standardization, there are four requirements for a robot to be termed as a cobot. Obliging to one or plurality of these requirements would enhance the safety of robot and position it as a collaborative robot (Cobot). The requirements are:

- Safety-rated monitored stop

- Hand guiding

- Speed and separation monitoring

- Power and force limiting

- Safety-rated monitored stop: These cobots employ sensors to detect the presence of human beings and automatically stop working when a worker enters a predefined area. The human workers can resume the cobot’s operation with the push of a button. These cobots are ideal for industrial tasks requiring help with little human involvement. They employ a variety of safety sensors in addition to stopping the cobot when it gets too close to its human coworker.

- Hand guiding: These cobots enable operators to physically guide them through a task. For example, the programmer can show the cobot how to complete the tasks by guiding it with their hand. With this function, it’s simple to reprogram the cobot without having to change the software. These cooperative cobots have a short learning curve, which reduces downtime.

- Speed and separation monitoring: These cobots employ sensors to keep a safe distance from human workers and have features comparable to the safety-rated monitored cobots. But these cobots have more advanced features. For instance, a machine vision system continuously monitors its two operational zones — the warning zone and the stop zone. When it notices motion near the warning zone, the cobot’s vision system slows it down to a safe speed. The cobot promptly stops working when a person enters the stop zone and resumes once the person has left the area.

- Power and force limiting: Built to reduce the risk of injury, these cobots are restrained in the amount of force they can exert on their environment. They’re built with rounded corners and no sharp edges because they’re designed to work alongside humans without additional safety measures such as barriers, vision systems or external scanners. These cobots further improve human safety by not having exposed motors or pinch points where a person or part of their body could get caught. Because of their built-in intelligent collision sensors, these collaborative cobots automatically stop working when they encounter a human coworker. They’re typically more flexible but also smaller, slower, and less powerful than conventional robots.

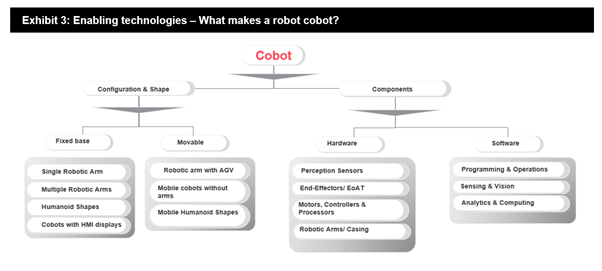

Cobots: Enabling Technologies

Cobots are equipped with software-controlled sensors that enable them to detect objects, people, and potential collisions to keep safety at paramount and end effectors like grippers for robotic manipulations. Furthermore, cobots also include:

- Sensors: Mounting a force/torque sensor on a robot arm makes the cobot more intelligent. With the help of the sensor during valve insertion, a robot will move to the direction where less force is felt. The capability of using the sense of touch expands the options for automation and allows companies to automate monotonous, repetitive work.

- Vision Systems: Vision systems are the eyes of cobots. Cameras and depth sensors capture visual data, enabling cobots to recognize objects, locate targets, and navigate autonomously. Machine vision algorithms analyze images, ensuring precise part recognition in manufacturing or assisting with pick-and-place tasks. This technology enhances cobots’ adaptability to diverse tasks and environments.

- Grippers: Grippers are cobots’ hands, and their design is critical for task versatility. Cobots can use various grippers, including vacuum, pneumatic, and adaptive grippers, to handle different objects. Adaptive grippers, with their ability to conform to object shapes, are especially useful for handling irregular items. Gripper technology advances enable cobots to grasp, manipulate, and release objects with precision, making them more versatile in applications such as assembly and material handling.

- Cobot Programming: Cobots are much easier to program as they don’t require specialized knowledge, eliminating the need for cost intensive robotic integration. This also cuts cobot deployment costs.

With drag-and-drop programming, users translate their actions into code, simplifying cobot programming. Just drag and drop actions in the right order to complete tasks. Some cobots allow users to sketch program layouts using buttons to guide the robot. Both methods are user-friendly, enabling more workers to interact effectively with the robot. Some cobot manufacturers go further, offering application wizards to simplify complex tasks, like configuring an end-of-line palletizing robot, reducing setup time.

Overall cobots offer user-friendly programming, adapt to various tasks, and lower upfront costs in industrials setting.

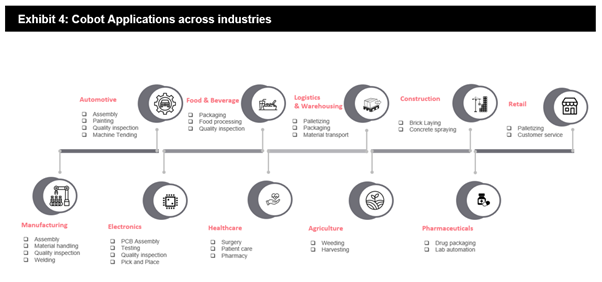

Applications/ Use Cases for Cobots

Cobots co-exist in diverse applications across industries. Their intelligence, along with flexibility and productivity, are highly desirable qualities for any manufacturer looking to maximize return on investment (ROI). Cobots are widely used in industries such as food, packaging, logistics, construction, semiconductors, retail, manufacturing, healthcare, etc.

Some popular domains with end applications for cobots are detailed below:

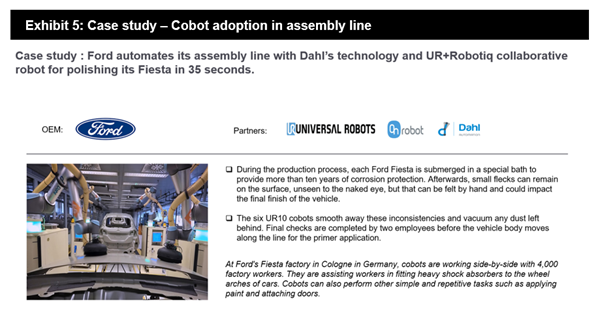

- Manufacturing: Cobots help operators in manufacturing processes, such as welding, dispensing, assembly, or product inspection. They improve the quality, efficiency, and safety of the production lines, while reducing costs and waste. Exemplary companies that use cobots in manufacturing are BMW, Ford, Volkswagen, and Samsung.

- Logistics: Cobots assist workers in logistics tasks, such as picking and placing, packaging, or conveyance through a facility. They optimize the storage, distribution, and delivery of goods, while increasing the speed and accuracy of the operations. Exemplary companies that use cobots in logistics are Amazon, FedEx, DHL, and Walmart.

- Healthcare: Cobots support healthcare professionals in various services, such as surgery, rehabilitation, diagnosis, or patient care. Cobots can enhance the quality, accessibility, and affordability of healthcare delivery, while reducing the risks and errors. Exemplary companies that use cobots in healthcare are Intuitive Surgical, Medtronic, Hocoma, and Mabu.

- Education: Education is a new application for Cobots. Cobots can collaborate with human workers in educational activities, such as teaching, tutoring, mentoring, or research. In a world where virtual classrooms are gaining popularity, cobots can enrich the learning experience by acting as a moderator and physically representing the candidate who is sitting at a remote location. Thus, they can generate more interactive & personalized experience for the candidates. Some of the companies that are experimenting with cobots in education domain are SoftBank Robotics, Wonder Workshop, and RoboTutor.

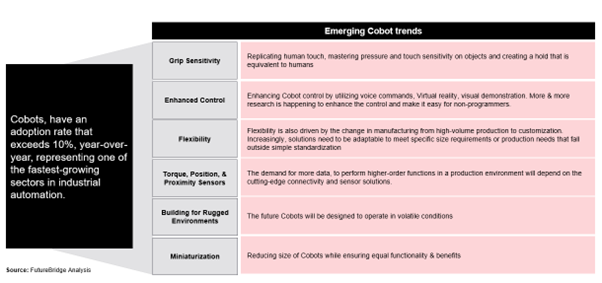

Cobots: Technology Evolution Adaptation Trends

As discussed in the previous paragraphs, safety and collaborative working are paramount criteria for any industrial robot to act as a cobot. Thus, most of the technological evolution for cobots is centered around these two themes only.

Cobot developers & manufacturers keep on adding functionalities in form of new parts, highly accurate sensors, various data gathering & analysis means, improved working mechanisms, inclusion of AI & ML, data transmission, and communication to enhance the collaborative working and improve the operator safety. Following are some of the key advancements to watch:

- Perception sensors: Multiple sensor solutions enable perception capability of a Cobot to co-exist with human. Converging AI with perception sensors will be essential to enable Cobots to truly interact, anticipate, and communicate, especially when they need to hand off certain complex tasks to humans.

- AI & ML Integration: Having sensors is not enough. Making decisions by judging the behavior of a coworker is an essential requirement for safety & collaboration. The cobot must learn from the working pattern of various users before acting. In a world where collaborative working requires multiple users working on a single product/ task, robots also need to understand the worker behavior to ensure safety of each individual working in vicinity of the cobot. AI & ML come as a blessing here and ensure proper analysis of the environment. While the earlier robots would struggle to detect the working pattern of various users and would shut to prevent any harm, the new generation cobot can adapt with workers and keep working without sacrificing efficiency and productivity.

- Cloud Computing & Connectivity: Industrial operations are of many kinds. For true automation and high productivity, a robot should learn from similar instances worldwide and adapt its working settings to ensure it can deliver the same output with least training. Thus, organizations are using cloud computing and connectivity. When similar tasks are done by cobots at various locations, the centralized repository of the data can be maintained at cloud and data can be shared with all participant cobots. Thus, learnings from one location can be quickly imitated at another location and the cobots can collaborate with high productivity.

- Edge Computing & AI: Cobots need much closer control for real-time implementation of complex decisions in co-working environments. A lot of operations require making decisions on the end node where the data is generated and unaltered. These are unique situations which are not present on other sites and thus the decision making also needs to reflect the same attitude. That’s one area where edge computing comes in picture. Since the data gathering, analysis and response making is done at the edge node, the decision making is quick, more realistic, and highly effective.

- End-of-arm tooling: This is the most researched and worked field in cobots. The cobot industry cannot scale its operations if the cobots cannot be utilized for multiple purposes. In recent times, most of the research has been focused on identifying & developing the end-of-arm tools that can enhance the utility of cobots for various purposes. It includes designs of vacuum grippers, three finger grippers, magnetic grippers, pressure sensitive gripping mechanisms, EoAT with welding guns, etc.

These EoAT systems can handle a variety of materials with various shapes and properties. Further, the embedded sensors that allow the cobot to adapt its grip according to the object’s surface properties, material, and weight. The development of end-of-arm tooling plays a key role in the value a robot can bring to its end-user and will contribute highly to the wide adoption of industrial robots in new industries. New developments in EoAT are focused on advancing technology and adaptation of cobots.

Programming & Training enhancements: Cobot developers are also working toward enhancing the adaptability of cobots by providing cobots with voice recognition and analysis capabilities. Furthermore, there are developments happening in task mimicking, identifying and copying worker actions, understanding movements and acting etc., These new capabilities will enhance the utility of cobots and would limit the effort that is required in training cobots. More and more workers would be able to command cobots with movements and speech and it would further accelerate the adoption of cobots in various work environments.

Cobot Ecosystem

The forecasts for Cobot markets show strong growth, with rising sales and new application scenarios being developed.

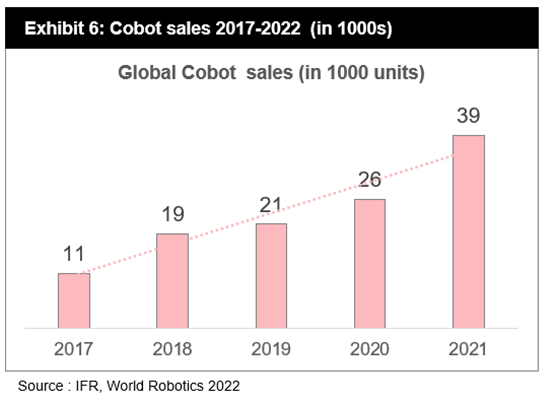

According to various reports, the collaborative robot’s market’s revenue stood at approx. $1 billion in 2022, with shipments increasing by ~20% to ~40,000 units. Collaborative robots have also seen some growth due to pandemic and labor shortage. The cobot market is expected to grow at a rate of ~50% in the next 5 years. North America, Europe, China, Japan, and South Korea are the geographical regions that would support this growth. Specific countries that would experience rise in market share are U.S., Canada, Germany, France, U.K., Italy, Russia, China, Japan, South Korea, etc.

The unexpected focus and demand of the industry due to COVID, labor shortage, rise in cost of manual labor, etc., have fueled the need for collaborative robots. More and more industries are now adopting cobots and working toward a collaborative set-up.

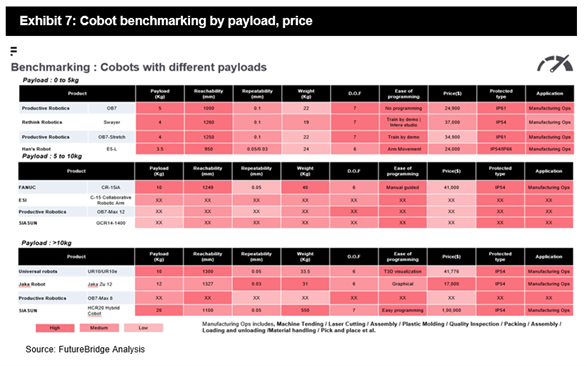

In terms of the size of robots, payload becomes a criterion of evaluation. There are multiple kinds of cobots from payload capacity of 0-5kg to 15kg and more. Our analysis suggests that more than half of the total cobot market is dominated by cobots with payload size 5kg or less. Less than 10% of the total cobot market contains cobots with payload 15kg or more.

We have done a benchmarking study to compare some of the leading cobots for their specifications and prices. It includes payloads, DOF, reachability, ease of programming, type of rating, and popular applications that cobot is serving. The study also throws light on the fact that cobots with low payload are not expensive. The average price of a cobot with a payload of 0-5 kg is around $23,000. The price goes up as the payload increases, but the price increase is consistent. For example, the average price of a cobot with a payload of 5-10 kg is around $34,000, and the average price of a cobot with a payload of 10-15 kg is around $41,000.

The price of cobots varies according to the maker, functionality, technical features, and the end-of-arm tooling used. When considering the use of a cobot in manufacturing, an organization should determine the precise ROI that justifies the expense.

Cobots typically cost between $10,000 and $50,000 USD. When selecting a platform, the cobot’s manufacturing quality should also be considered because the additional tooling will increase the cost.

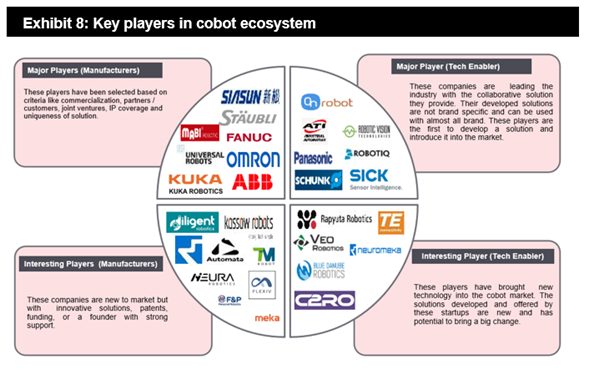

Cobots: Key Players in Ecosystem

At FutureBridge, we have segregated and analyzed cobots companies into multiple categories including manufacturers, technology enablers (end effectors, software developers, vision and sensing system enablers), cobot transforming companies, automation and AGV enabling companies, Actuator and mechanism development companies, etc., Please get in touch for any further information.

FutureBridge Insights

Cobots will co-exist in more industries, like healthcare, logistics, and customer service. There would be developments in ethical and regulatory rules to enhance safety and use of cobots. The ascent of artificial intelligence (AI), notably with advanced chatbots like OpenAI’s ChatGPT, driven by large language models (LLMs), will add a fresh face to the cobots of future. Work has already started in this direction; per latest update, companies like Doosan Robotics has partnered with Microsoft and Doosan Digital Innovation to give collaborative robots (cobots) a context-aware control system based on generative pre-trained transformer technology.

The future for cobots looks promising with many opportunities for cobot technology. In the coming times, the adoption of cobots would drastically improve and it would present unprecedented opportunities for the cobot manufacturing companies and other suppliers working in the value chain.

However, the buyers would also need to conduct evaluation to understand what kind of cobots would serve their needs and how much collaboration would be needed in short-&-long terms.

Cobot developers would need to identify their target audience and the expected markets to drive their innovation and development priorities. A systematic plan to expand from one application domain to others and a well-defined geographical expansion theme would do wonders in maximizing sales and market penetration. The technological developments, competitive advantage of various cobot offerings would also be highly dependent on audience and the expansion strategies.

For OEMs, and firms that plan to buy cobots, there would be multiple options to choose from. However, the companies would need to manage their expectations for profitability and productivity. Choosing the right cobots, understanding the extent of collaboration, and identifying the correct suppliers & IT support would maximize the profits in mid-term & long-term duration. As technology is adapting and evolving, there will be multiple sale options available to the buyers with variations in pricing, payment terms, offerings, technological capabilities, and expected IT support in future times. Thus, the utilization of technology would essentially be dependent on the firm’s strategy and not on the cobot.

Have Queries, we are here to help you:

Are you a cobot manufacturer?

- Who could be the audience of your cobot? Which Industries you should target first, and which geographies would be the ideal markets?

- Who should be your suppliers? What are their USPs? How do their offerings differ from one another?

- What technologies you should be focusing on? What should innovation journey look like?

- Where should you invest your R&D dollars?

- How are your competitors developing their products? What should you do to beat the competition?

Are you a buyer?

- Does it make sense to buy cobots? How much efficiency can you expect with cobots? How much would you gain using cobots?

- What type of cobot should you buy? Why should you prefer one supplier over another?

- What kinds of training would your operation team need?

- What do you need to do to make the transition smooth?

Need a thought partner?

Share your focus area or question to engage with our Analysts through the Business Objectives service.

Submit My Business ObjectiveOur Clients

Our long-standing clients include some of the worlds leading brands and forward-thinking corporations.

- © 2021 Cheers Interactive (India) Private Limited. All rights reserved. FutureBridge ® is a registered trademark of Cheers Interactive (India) Private Limited.